Rapid Roll Doors – The Cheetah S50

Series 50.

PVC Rapid Roll Door

Tested to the essential characteristics of EN13241: 2003 + A2:2016.

- High-speed operation – up to 1.6m/s, subject to door size

- Energy-saving

- High wind resistance (Class 5)

- Sound reduction

Our Series 50 ‘Cheetah’ rapid roll door is an energy-saving product designed for applications where speed, frequency of use, and durability are key requirements. Additionally, its robust design and high wind resistance make it ideal for larger and external openings.

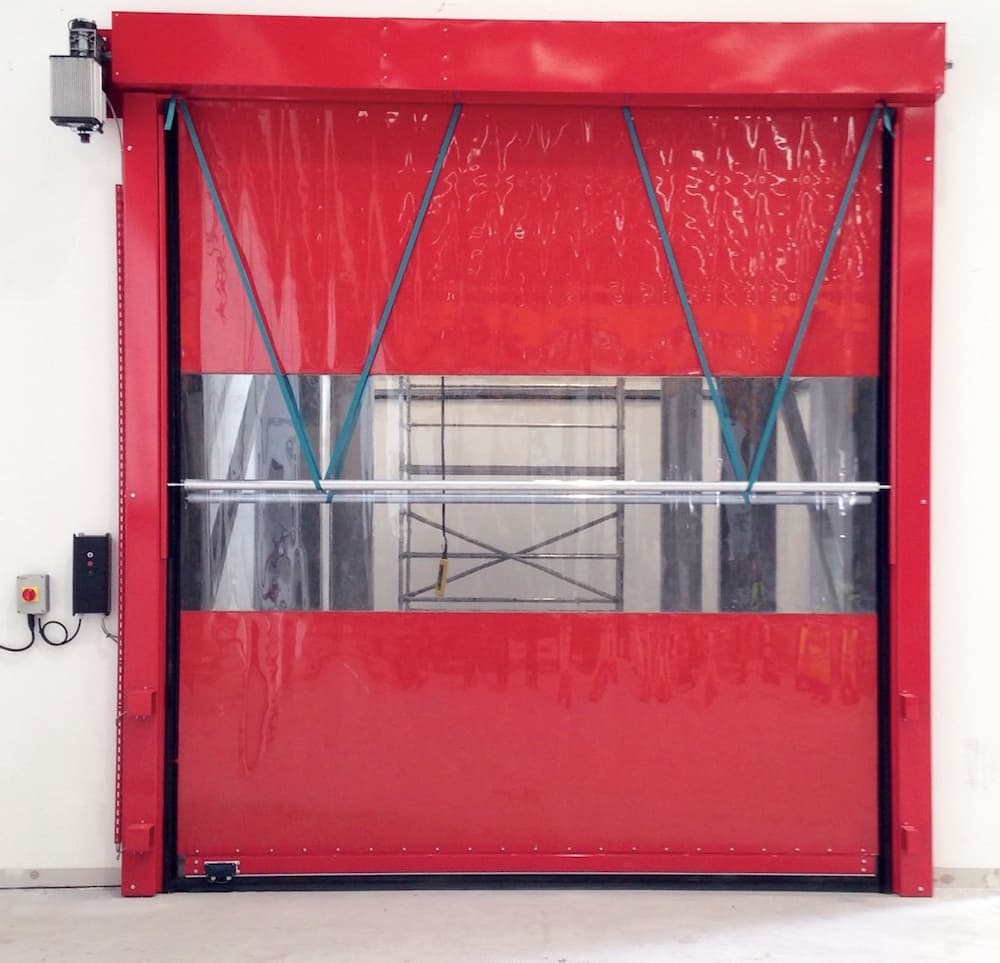

The shutter features a PVC curtain with a full-width vision section, providing optimal light transference. A heavy-duty steel guide system and bottom

rail provide enhanced strength and are powder-coated for a superior aesthetic finish.

Powered by a Safedrive® Fi operator, supplied by leading European door drive manufacturer GfA Elektromaten, the system ensures reliable performance. The Safedrive® Fi range features a built-in frequency inverter with easily programmable fast opening and closing speeds, along with a soft start/soft stop function. The drive system also includes a patented integral safety brake (anti-fallback device) and an emergency low-level hand chain operation facility in case of a mains failure.

The many actuation and relevant safety device options can be configured to suit the environment in which the door is installed, ensuring simple and safe automatic operation or the user, whether pedestrian, vehicular or a loading bay application.

Each design has been thoroughly tested and inspected by an accredited independent testing group enabling us to issue Declaration of Performance. Performance characteristics are according to harmonised standard EN 13241:2003 + A2:2016, giving our customers peace of mind that the door systems we manufacture are of the highest quality and are fully compliant with European directives.

All of our high-speed door systems are manufactured in house at our production facility in Wigan, Greater Manchester, and are subject to continuous product development ensuring the products we offer are of the highest quality whilst maintaining ease of installation.

Call us Today:

01942 683 601

Or Request a Callback >

A full-width vision section provides optimal light transference.

Durable acrylic end cassettes are fitted to each side of the robust bottom rail. These cassettes are designed to break upon high impact, effectively preventing costly damage to the curtain.

The door is supplied with anodised aluminium wind bars, fitted internally and externally, which run on high-quality nylon rollers, ensuring it withstands strong wind forces.

The Specification

| Colour Swatch:

- Durable PVC Curtain available in these colours:

| Specification:

- PVC Curtain with option of full width vision section

- Powered by GfA Safedrive® Fi operator with integral

anti-fallback device and built on frequency inverter - Opening speed of up to 1600mm per second, subject to door size

- Lintel brush, side seals and EPDM rubber bottom seal

- Self-monitoring, optical wireless Safety Edge system and

2 no. infra-red Photocell kits - Barrel canopy

- Heavy duty flag arrangement

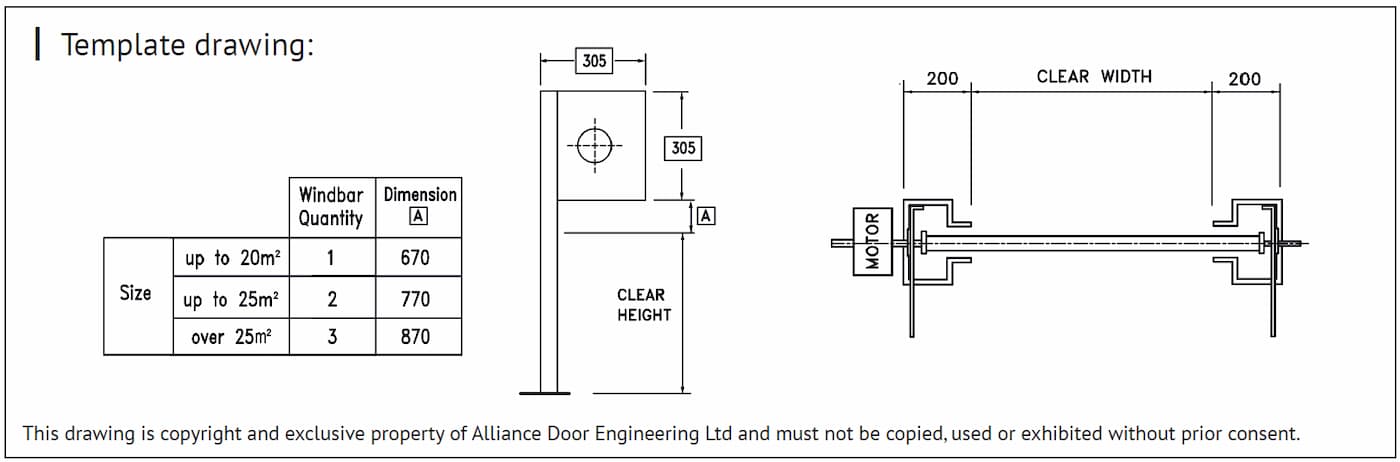

- Single internal an external wind bar system as standard. Double and triple wind bar systems are used when height, width or location dictate

| Options:

- Wide range of colour options

- Traffic Light System to control vehicular activity

- Motor cover for external applications

| Actuation Options:

- Push button control

- Radar Movement Sensor

- Induction Loop System

- Remote Control – Handheld and/or forklift-mountable transmitters

- Pull Cord

| Power Supply:

- 16A 5 pin commando socket fed from 16A c-type breaker, fitted 500mm from the motor side of the opening 1500mm from FFL.