Roller Shutter Chain Operated

Series 3.

Manual Chain Operated Industrial Roller Shutter

Tested to the essential characteristics of EN13241:2003 + A2:2016

- CE & UKCA Certified

- Assembled from high-quality components

- Wide range of colour options

- Simple and safe operation

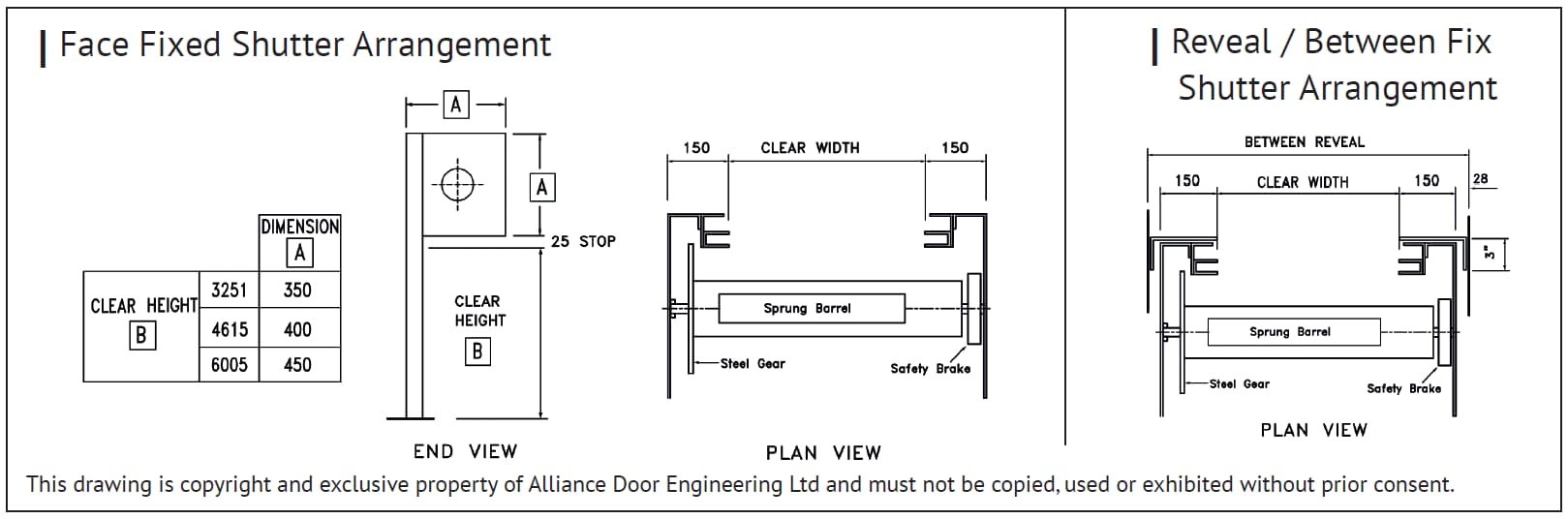

Our Series 3 Manually Operated Chain-Driven Industrial Roller Shutter is a robust product, ideally suited to protect commercial, industrial, or agricultural premises with openings up to 6000mm wide × 5000mm high. In addition, it provides ease of operation when mains electrical power is a constraint.

The shutter utilises hard-wearing steel components, ensuring a long lifespan, and a spring-loaded barrel provides a counterbalance to the weight of its curtain, making operation easier.

A standard feature within the design is a curtain assembled from solid 76mm scrolled lath, with additional options for a perforated or punched curtain should light transference, ventilation, or transparency be required.

The shutter can feature a plastisol (curtain only) or polyester powder-coated finish, available in a wide range of colour options.

Each design has been thoroughly tested and inspected by an accredited independent testing group enabling us to issue Declaration of Performance. Performance characteristics are according to harmonised standard EN 13241:2003 + A2:2016, giving our customers piece of mind that the door systems we manufacture are of the highest quality and are fully compliant with UK and European directives.

All of our roller shutter systems are manufactured in house at our production facility in Wigan, Greater Manchester, and are subject to continuous product development ensuring the products we offer are of the highest quality whilst maintaining ease of installation.

Call us Today:

01942 683 601

Or Request a Callback >

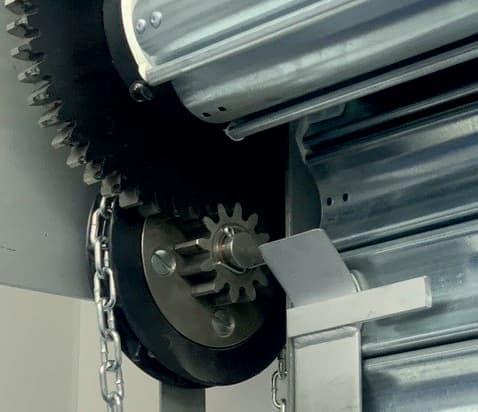

The barrel is driven by steel intermeshing gears which ensures a low maintenance, longlife span

The shutter is operated via a haul chain system, assisted by a spring-loaded barrel, providing a counterbalance to the weight of its curtain, making operation easier

Anti-fall device (safety brake) at the non-drive end of the barrel, which will prevent the door from dropping suddenly in the unlikely event of a mechanical component failure.

For additional security, a ground lock or guide mounted bullet locks can be added

Compact and unobtrusive design

Wide range of colour options

The Specification

| Specification:

- Curtain assembled from solid, 76mm curved steel lath

- Heavy duty flag arrangement

- Double reduction steel gear system for shutters > 18sq.m

- Spring assisted barrel assembly

- Galvanised finish as standard

- Wind locked guides as standard for openings > 3999mm

- Safety Brake (anti-fall device)

- Zinc plated chain keep system

| Options:

- Wide range of colour options – polyester powder coated to a RAL or BS colour or plastisol coating to curtain exterior

- Perforated or punched

- Barrel canopy for external applications

- Bottom weather seal

- Soffit seal (4” top brush)

- Side brush seal

- Guide mount bullet or ground locks

- Wicket gate for pedestrian access